Chemical Synthesis

appreciate that chemical synthesis involves the selection of particular reagents to form a product with specific properties

- Chemical synthesis processes involve selecting specific reagents and reaction conditions to optimise the rate and yield of the product.

understand that reagents and reaction conditions are chosen to optimise the yield and rate for chemical synthesis processes, including the production of ammonia (Haber process), sulfuric acid (contact process) and biodiesel (base-catalysed and lipase-catalysed methods)

Haber process

- The Haber Process is the production of ammonia

- The formation of ammonia occurs naturally with nitrogen fixing bacteria known as nitrogenase (enzyme)

As temperature increases, Kc decreases.

Although the reaction is exothermic, which would imply that a lower

temperature is required for the forward reaction to be favoured, by

lowering the temperature, the reaction yield would decrease. This is

because at lower temperatures, the rate of reaction decreases because

there is not enough energy in the system for the collisions to exceed

the activation energy. Therefore, a moderate temperature is required,

so that the rate of reaction and reaction yield are maximised, and this

is achieved by temperatures from 400-500oC.

Contact process

- The contact process is the formation of sulfuric acid (H2SO4)

understand that fuels, including biodiesel, ethanol and hydrogen, can be

synthesised from a range of chemical reactions including, addition, oxidation

and esterification

describe, using equations, the transesterification of triglycerides to

produce biodiesel

- Biodiesel is a fatty acid alkyl ester made from fats and oils

- Advantages

- Disadvantages

Transesterification

- Reaction

understand that fuels, including biodiesel, ethanol and hydrogen, can be

synthesised from a range of chemical reactions including, addition, oxidation

and esterification

describe, using equations, the production of ethanol from fermentation and

the hydration of ethene

understand that enzymes can be used on an industrial scale for chemical

synthesis to achieve an economically viable rate, including fermentation to

produce ethanol and lipase-catalysed transesterification to produce biodiesel

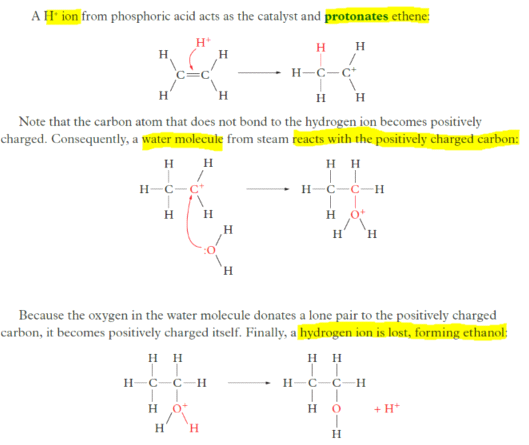

Hydration of ethene

understand that fuels, including biodiesel, ethanol and hydrogen, can be

synthesised from a range of chemical reactions including, addition, oxidation

and esterification

discuss, using diagrams and relevant half-equations, the operation of a

hydrogen fuel cell under acidic and alkaline conditions.

calculate the yield of chemical synthesis reactions by comparing

stoichiometric quantities with actual quantities and by determining limiting

reagents.

- Limiting reagent is the reactant in a chemical reaction that determines how much of the products are made

- Percentage yield in a multistep synthesis is the product of the percentage yield for each individual reaction